How a Light Guide Manufacturer Smooths the Path to Production

You already know that bringing a product or innovation to market takes careful consideration. From the initial planning stages to production, there are complex decisions you need to make during a project lifecycle like which manufacturing options to choose. When it comes to light guide manufacturing, however, an experienced light guide manufacturer removes some of those decisions from your shoulders.

Our team collaborates with leaders at original equipment manufacturers (OEMs) throughout the project lifecycle. From initial research to final prototype approvals and production, the experts I work with are on hand to ask the right questions that help your team make strategic decisions. One key choice our engineers support on is selecting the best light guide production process for each project.

Thin film embossing, or roll to roll embossing, is one method for light guide manufacturing. If you’re unfamiliar with this process, continue to learn more!

What is Thin Film Embossing?

Thin film embossing is a specialized manufacturing method we use to emboss precise optical patterns on light guide plates. This manufacturing method is ideal for applications that require high production volumes of light guides with simple geometries.

Thin film embossing uses a thin polycarbonate film, typically 0.8mm to 0.15mm, which is die cut to its final size. While common manufacturing methods like injection or extrusion molding are used more frequently, thin film embossing has its benefits. The most notable is the capability for incredibly thin, flexible light guides. Another benefit is the quick turnaround on production. Efficiencies in thin film embossing are due to the automated process, which we’ll cover in another section.

At Global Lighting Technologies, we create custom optical patterns for each light guide project no matter which production method we leverage. You can learn more about our entire light guide manufacturing process and our other production methods here.

A Light Guide Manufacturer Approach to Thin Film Embossing

The thin film embossing process unfolds in a series of well-orchestrated steps at our Zhongli, Taiwan facility, which you can learn more about here.

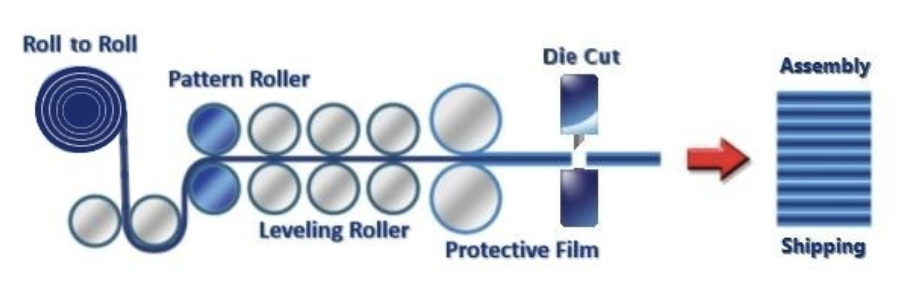

Our process for thin film embossing is as follows:

- A polycarbonate film roll is inserted into the embossing machine.

- The film moves through several rollers to ensure the film is completely flat.

- Next, the embossing drum places the custom optical features on the polycarbonate.

- Once pattern is placed, the film goes through a series of leveling rollers to eliminate warpage.

- Then, a release liner, or protective film, is applied to both side of the polycarbonate for protection.

- More rollers continue to level out the film.

- Finally, the film is die cut then moved to assembly and shipping.

Aside from the roll being placed inside the machine and final cut parts taken for assembly, the thin film embossing process is almost entirely automated. This contributes to precision even in the face of high capacity and often a quick turnaround time.

Common Applications for Thin Film Embossing

Thin film embossing offers many applications across industries where thin, flexible and precisely patterned light guides are essential. For example, key applications include keyboard backlights, front lights for eReaders, wearables and any other thin, flat part requirements. Learn more about the differences between backlights and front lights from one of our team members.

One customer collaborated with our team to create a hat with an illuminated logo on the front. The light guide had to be thin enough to fit into the hat, yet powerful enough to illuminate the logo. Consequently, thin film embossing was the ideal manufacturing method to accomplish this.

It’s important to know when to leverage thin film embossing; likewise, it’s equally as important to know when a project requires a different approach. Thin film embossing may not be the optimal choice for applications where low production volumes or non-polycarbonate materials are called for.

Efficient Production, Expert Support

In essence, thin film embossing presents a streamlined production solution for OEMs. When your project requires high-volume production of light guides with exceptional brightness uniformity and precision optical patterns, thin film embossing is a strategic option. We feel confident in recommending thin film embossing for unparalleled flexibility and precision to meet the evolving demands of modern applications.

Are you interested in learning how you can leverage thin film embossing for your next illumination project? Connect with our team here.

Learn more about how our thin, flexible technology meets the future of lighting.