How Do Light Guides Impact Your Device or Application’s Efficiency?

Light guide efficiency: it’s a topic I see bubbling on the surface, although not often discussed outright. It’s likely you’ve experienced the demand for energy efficiency across the board lately, from consumers to your partners throughout the supply chain. Yet, meeting energy efficiency benchmarks can feel complex because there are many factors to consider, and they aren’t all easily controlled.

For original equipment manufacturers (OEMs) that create devices or applications with illumination, we recommend a focus on what can be controlled, like:

- Light guide design

- Optical pattern design

- The number of LEDs and their placement

- Light guide films

These decisions are made easier when you have a trusted team of engineers and illumination experts at your side. Below, I share how our collaborative, innovative approach to design increases light guide efficiency. Plus, our engineers explore how the materials we use and strategic component placement lead to a reduction in power consumption across different industries like consumer electronics and automotive.

Light Guide Energy Efficiency Technology Innovations & Industries They Impact Most

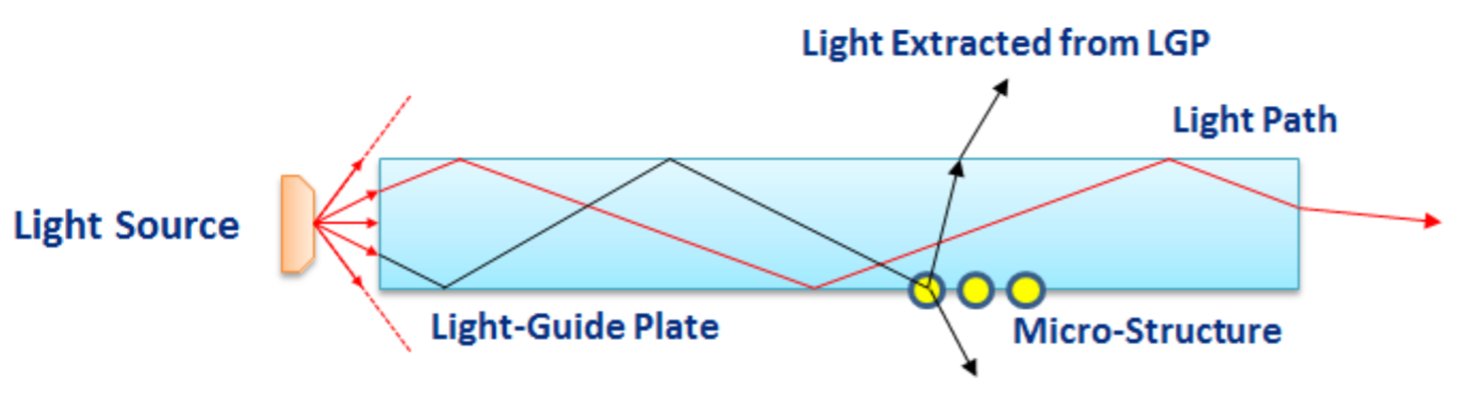

Significant technological advancements in light guide energy efficiency have occurred in recent years. Ultra-thin light guides enhance efficiency through total internal reflection, illustrated below.

This means light bounces within the guide, allowing for more light extraction through optical patterns, which increases overall efficiency. We cover total internal reflection more in depth here. In certain applications, this phenomenon also decreases the number of LEDs required or allows for lower-power LEDs. Both are crucial for energy conservation and efficiency in your device or application!

Our team noted the first strong push for light guide energy efficiency in the consumer electronics industry. This sector’s rapid growth, driven by the demand for smaller, thinner components in devices like phones, watches and laptops, required more efficient light guides. Smaller devices require smaller batteries, emphasizing the need for efficiency in every component, like light guides. This move towards energy efficiency not only supports the trend for compactness but also contributes to overall energy conservation. Likewise, the automotive industry has also made strides in light guide energy efficiency.

If you’re an OEM in either industry and your illuminated applications are battery-powered, I recommend custom light guides to achieve maximum energy efficiency. As mentioned earlier, this is a demand you’ve likely experienced not just from consumers, but your partners up and down the supply chain.

Meeting Energy Efficiency Requirements Through Design & Materials

The design and materials used in custom light guides directly impact your device or application’s energy efficiency. From LEDs to the materials in the light guide stack up, each component should be carefully vetted based on brightness and uniformity requirements unique to your application.

The first area our team evaluates for optimal energy efficiency is the light source. For many applications, we recommend thinner next-generation LEDs. Advancements in LED technology pack more power in a smaller component than previous iterations. In some cases, however, we’re unable to use the most efficient LEDs due to the thickness of the light guide. This is where our patented optical patterns come into play. Even when the most efficient LEDs can’t be used, we can design an optical pattern in such a way that it extracts light and optimizes its output. Learn more about our custom approach to optical pattern design here.

Another component that contributes to energy efficiency in the product stack up is a Brightness Enhancing Film (BEF). It sits on top of a light guide and can increase the brightness output that the end user perceives. Unless controlled, the light shoots off in different directions; a BEF extracts light in one direction, so less light is wasted. We pair BEFs with low-powered LEDs to simulate a similar brightness that a high-powered LED produces. The result is that less power is used but the desired brightness is achieved. While the film doesn’t increase the brightness or the light coming from the LED, it does control how brightness is perceived.

Edge reflectors are another way we can increase light guide efficiency. We use them to stop light from exiting the light guide. Light is lost if it reaches the edge of the part without interacting with an optical extraction feature. This is where edge reflectors come in. They bounce the light back into the light guide so it can interact with the optical pattern and be extracted.

Our Custom Approach

Regardless of how focused you are on light guide energy efficiency and reducing power consumption, we take a fully custom approach to your application. When energy efficiency is a top requirement, however, there are specific considerations we take at the onset.

First, we evaluate which LEDs to use depending on power requirements and brightness output. Next, we optimize the optical pattern and light guide thickness to maximize light extraction based on the application end goal. These two key steps, along with films and other component selections, occur during the design phase of our proven process.

The prototyping phase confirms if our component selections and design meet the project requirements. At the Global Lighting Technologies US facility, our team creates prototypes to measure brightness output and the energy required to power final LEDs selections. If the prototype is satisfactory, it will move to production in one of our five global manufacturing facilities.

High-Efficiency Light Guide Implementation

If you’re an OEM that’s hesitant to upgrade to energy-efficient light guides, that’s understandable. It’s an investment of time and capital; however, the payoffs can’t be overlooked:

- Application longevity: This is especially impactful in the consumer electronics and automotive industries where devices are commonly battery powered.

- Space maximization: Powerful, energy-efficient light guides allow more room for your technology in a smaller housing unit.

- Sustainability: Consumers and other stakeholders demand reduced power and resource use; high-efficiency light guides that last longer taps into this sentiment.

Each of these benefits supports the potential for increased end consumer satisfaction and revenue.

Future Directions for Light Guide Energy Efficiency

Light guide manufacturers, including ourselves, strive for the thinnest, most efficient light guides possible. Beyond this, one of our newest innovations is tapered technology which solves for when an efficient, ultra-thin light guide suffers from poor LED coupling. This can result in light loss at the top or bottom of the light guide. We mitigate this by tapering the end of the light guide to better match the LED’s size. This approach not only improves the fit but also enhances the light guide’s efficiency while still using the necessary LED.

Do you have energy efficiency or power consumption illumination goals you’d like to discuss? Or perhaps an innovation you’d like to bring to market? Our team can support. We understand that light guide manufacturing can feel complex – we’re on hand to streamline your efforts. Connect with the Global Lighting Technologies team here.