The Importance of Optical Patterns in Light Guide Design

Why do optical patterns matter in light guide design? Are all optical patterns created equally? Customers consistently ask my team these questions time and again. My answer is always the same: A final product can’t effectively meet performance and aesthetics targets without precise and high-quality optical patterns.

At first glance, optical patterns may seem like a minor detail in the grand scheme of designing a light guide. Yet, they’re essential to the solutions that light guide manufacturers provide.

Understanding how optical patterns contribute to better-performing light guides can provide a significant competitive edge. Read on for the history, importance, and customization capabilities of our optical patterns, with some key insights I’ve gathered while at Global Lighting Technologies.

The Evolution of Our Optical Patterns

If you’re unfamiliar with optical patterns, my team created this helpful primer. For nearly three decades, our optical patterns have impacted industries ranging from consumer electronics to automotive manufacturing, delivering precise, reliable, and energy-efficient lighting solutions. We’re proud to have been at the forefront of these advancements with patented optical patterns. Here’s a deeper look at our optical pattern innovation journey.

A History of Innovation

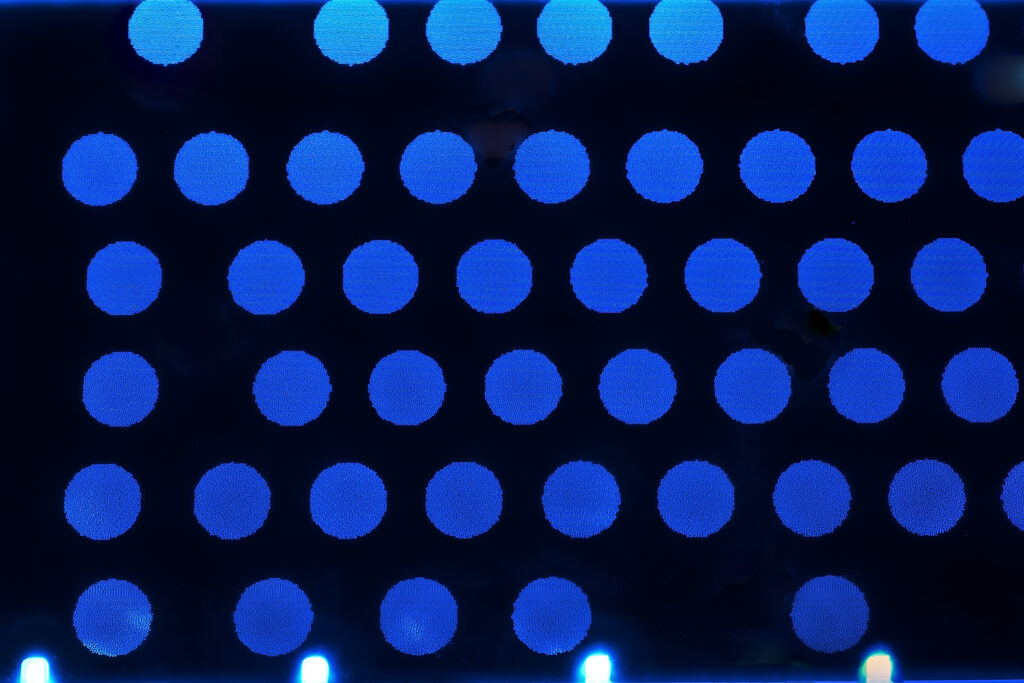

Starting in 1995, we developed our first printed light extraction patterns. This technology used a controlled density of white dots on light guides to create uniformly distributed light. By 1997, we introduced MicroLens light extraction technology, which was a game-changer. It enabled light extraction patterns to be integrated during the injection molding process, making production more efficient and accessible while ensuring brighter end products.

Fast forward to 2000, Global Lighting Technologies was formed to merge optical design expertise with high-volume manufacturing. This strategic move supported the expansion of our technology into various industries. Over the years, breakthroughs like optical lensing in light-redirecting films (2004) and variable optical elements for embossed thin film light guides (2008) have helped our clients achieve breakthrough success.

Today, we hold over 350 patents for optical light guides, films, systems, and manufacturing techniques. A major milestone in recent years has been our micro-machined structures. We pioneered this unique application, where mirror-finished structures allow for the directionality of the light path. These innovations allow us to create features on much smaller scales than ever before—a crucial benefit for modern applications like automotive, consumer electronics, and medical devices.

Overcoming Challenges in Development

One challenge of our early processes was creating optical pattern lens designs that performed well in lab settings but were also feasible to mass-produce. Engineers had to work collaboratively across disciplines to develop optical lenses that met performance and manufacturability requirements.

Let’s move on and explore how our optical patterns and light guide designs create solutions for global OEMs across diverse industries.

Applications and Industry Customizations

Certain industries, particularly high-end consumer electronics and automotive, demand some of the most intricate and advanced optical designs due to their complex requirements. By leveraging our robust database of previously designed optical features, we can select and fine-tune those most appropriate for individual applications.

Recent Light Guide Design & Optical Pattern Success Story

One of our standout projects involved custom optical patterns for the world’s smallest AED. For this critical medical device, our team ensured that the optical patterns delivered brightness uniformity essential for visibility in emergency situations. The project’s success underscores how impactful optical patterns and light guide designs can be in real-world applications.

Meeting Evolving Demands

Flexibility is at the heart of our design philosophy. While the patterns themselves may not physically transform, our approach to application-specific customizations ensures consistently high-quality outcomes. By aligning each project with the customer’s industry requirements and design goals, we help OEMs innovate faster and smarter.

Why Our Optical Patterns Stand Out

Fueled by nearly three decades of light guide design and manufacturing expertise, we prioritize research and development to stay ahead of emerging technologies, applications, and industry demands. Our optical patterns are part of this commitment.

Precision and Reliability at Scale

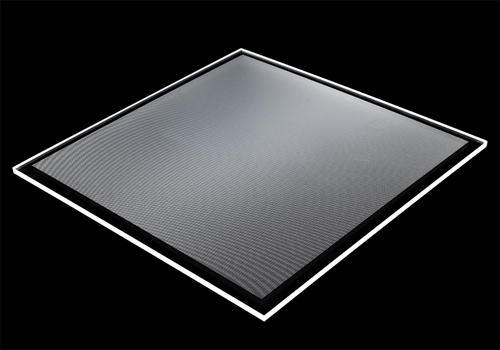

Unlike manufacturers relying on print-screened light guides with large, conspicuous dots or chemical-etched designs filled with imperfections, our optical patterns deliver on both looks and performance.

With advanced techniques, we can produce reliable, mass-manufactured optical light guides for a fraction of the cost other high-tech processes require. The result? Products that elevate brightness, uniformity, and overall performance—all while enabling lower production costs.

Tailored for Optimal Performance

The optical pattern we use for each project is customized based on our database of patterns. Our collaborative process begins when we know a customer’s light guide mechanical requirements. From there, we consider design constraints—spatial allowances, LED power availability, and brightness or uniformity expectations. Each pattern is tailored to the customer’s application, ensuring seamless integration and optimal performance.

For example, our approach allows us to fine-tune distribution patterns, ensuring better brightness uniformity or adding targeted directionality. Whether designing light guides for automotive displays or compact consumer electronics, our tailored patterns provide unmatched flexibility in the industry.

The Competitive Edge

Ultimately, precision and cost-effectiveness come together to make our optical patterns a game-changer for OEMs. By investing in customized design from the earliest stages of product development, our customers can bring superior light guide solutions to market faster, reducing the risks of delays or revisions.

Why Light Guide Design Is the Future

Creating advanced light guides with pinpoint precision is vital in today’s interconnected world. Light guides are central to how we interact with technology, from sleek automotive dashboards to futuristic consumer wearables and vital medical applications.

Our patented optical patterns provide OEMs a reliable partner for tackling these challenges. Through decades of refinement, innovation, and dedication to customer outcomes, our patterns offer a proven path to success—effortlessly combining style, functionality, and cost-efficiency.

Whether you’re in consumer electronics, medical devices, automotive, or beyond, working with a seasoned optical pattern partner could be the key to unlocking your next breakthrough in light guide design. Contact our team today to explore what’s possible. ssibilities are brighter than ever. Reach out to our team to get started on a custom light guide design.