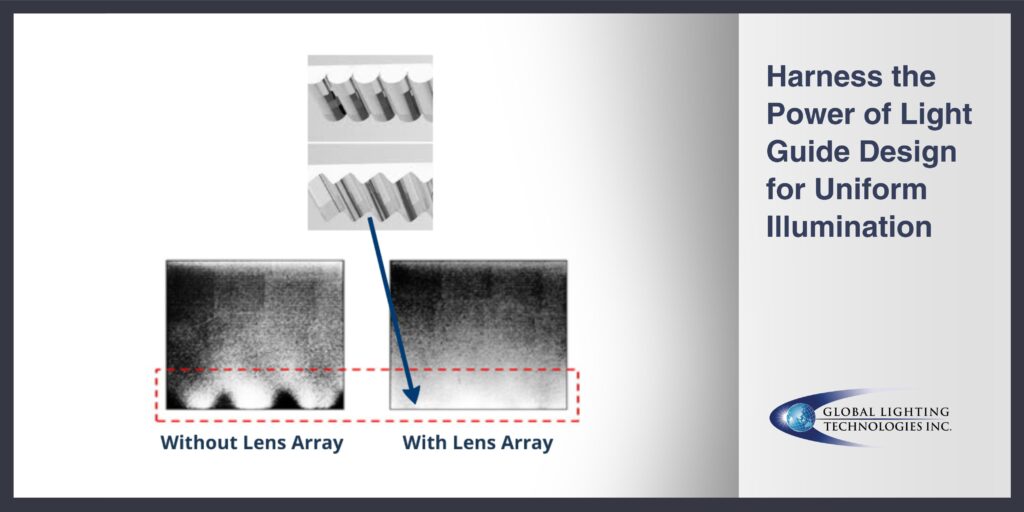

How Light Guide Design Enhances Uniform Illumination

Uniform illumination isn’t just an aesthetic enhancement. It’s a necessity. When supported by effective light guide design, uniform illumination can define user experience, differentiate products, and provide tangible efficiency benefits.

At Global Lighting Technologies, I’ve seen time and again how light guide design plays a pivotal role in creating solutions that deliver precise, uniform illumination across a range of industries. Here, I’ll share insights into the significance of uniform illumination, the challenges of achieving it, and how our team’s expertise makes an impact in diverse markets.

Why Uniform Illumination Matters

Uniform illumination refers to the even distribution of light across a surface, ensuring there are no dim or overly bright spots. For Original Equipment Manufacturers (OEMs), this can mean the difference between a product that blends seamlessly into its environment and one that detracts from user satisfaction.

Key Benefits for OEMs:

- Enhanced Appearance: Uniform lighting makes products visually appealing and separates them from competitors whose lighting may appear inconsistent or subpar. This visual edge can drive consumer preference and brand loyalty.

- Superior User Experience: Non-uniform lighting can distract or confuse users, particularly in critical applications like medical devices or egress signage, where clarity is paramount.

- Improved Efficiency: Traditional methods of achieving uniformity often rely on excessive LED usage, which increases power consumption. GLT’s innovative light guide designs reduce the number of LEDs needed, minimizing energy use without compromising performance.

Take OOONO Medical AED, for example. This device leverages our light guide technology to provide clear, uniform illumination—essential for its life-saving functionality. Similarly, in display technologies, where users expect flawless lighting, uniformity ensures the product’s success in meeting high consumer expectations.

Industry-Specific Illumination Standards

Different industries demand varying levels of uniform illumination, and I’m proud that our team tailors designs to meet these unique needs.

- Automotive: High-end vehicles often require illuminated displays, mirrors, and dashboards with exacting standards for uniformity and brightness.

- Consumer Electronics: Devices like ring lights depend on precisely controlled light propagation to maintain uniformity around curves.

- Medical Devices: Products like the OOONO AED require clear, consistent lighting to communicate critical information effectively.

- Egress Lighting: Exit signs, especially those in regulated markets like Europe, must meet stringent performance metrics to ensure safety and visibility.

In each industry, the goal is to optimize light distribution, ensuring products meet uniformity requirements.

Overcoming Challenges in Light Guide Design

Designing for uniform illumination isn’t without its hurdles. Mechanical constraints, power availability, and industry-specific standards all add layers of complexity.

These are the most common challenges my team and I come up against:

- Mechanical Design: The shape and size of a product can limit LED placement, necessitating innovative light guide designs.

- Power Restrictions: Applications like battery-operated devices must balance energy efficiency with uniformity, a challenge we address with advanced optical designs.

One of our most challenging yet rewarding projects involved ring lights, where LED placement and optical patterning were crucial to achieving uniform illumination. Through iterative adjustments, we ensured light traveled seamlessly around the curve, delivering both functionality and aesthetic appeal.

Customer Success Stories

Our light guide solutions have transformed products across industries. Here are some highlights:

- Automotive: Our LED backlights enhance the performance of full display mirrors, an LCD application where uniformity is a necessity for the user experience.

- Consumer Electronics: As mentioned, we’ve found uniformity success even when we’re up against light traveling around a curve and the need to propagate it effectively.

- Medical Devices: The OOONO Medical AED from earlier relies on our uniform lighting to ensure clarity and precision for its users.

- Exit Lighting: exit signs in many markets often require strict performance benchmarks that we’re proud to meet!

In each case, we’ve turned customer challenges into opportunities, using advanced light guide designs to deliver superior outcomes. Whether addressing strict brightness standards or creating visually stunning effects, our solutions consistently exceed expectations.

The Future of Light Guide Design

As industries evolve, the demand for uniform illumination will continue to grow. My team remains committed to pushing the boundaries of light guide technology, creating innovative designs that enable OEMs to achieve their goals with efficiency and style.

Whether the goal is to reduce power consumption, enhance user experience, or meet rigorous industry standards, I’m proud that we’re at the forefront of light guide design. For OEMs seeking a competitive edge, uniform illumination isn’t just a feature—it’s a game-changer and the possibilities are brighter than ever. Reach out to our team to get started on a custom light guide design.