A Major Consumer Electronics Company Achieves Success with Global Lighting Technologies (Again)

For one major consumer electronics company, sights were set on illuminating the next generation of smartwatches. This Global Lighting Technologies customer returned to our team for expert light guide design support. Our collaboration resulted in a new smartwatch with an illuminated display to be sold on the market. Read on to learn more about this exciting project.

The Opportunity

This customer’s goals and expectations were clear: achieve uniform brightness and illuminate the display on the watch with a profile and bezel that was as thin as possible. On the surface, this sounds simple; however, there were several engineering hurdles to overcome. Our team approached this challenge as an opportunity to innovate.

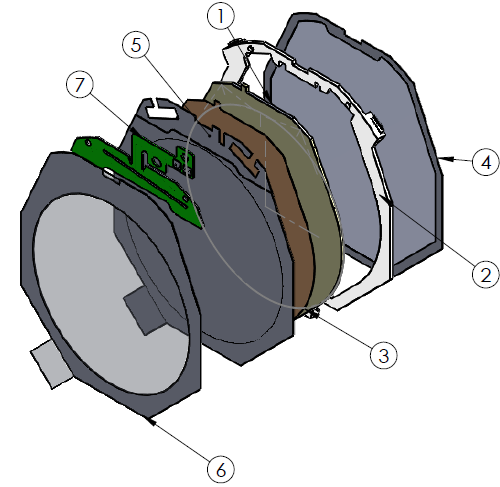

One consideration was the consumer demand for a thin device. Even though new technology allowed for advanced processing and other features to be thinner, there is only so much space available in a watch. Our light guide needed to be thin yet powerful enough to fit within tight limitations.

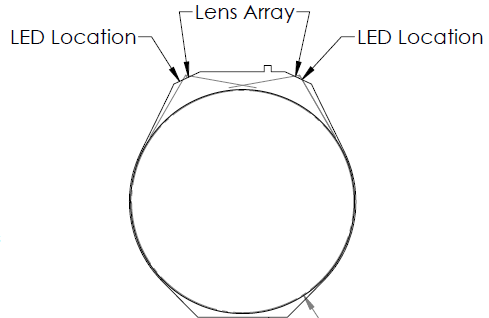

Another opportunity for innovation was to achieve the customer’s extremely thin bezel goal. Our team needed to design the backlight so that the LEDs situated along the edge of the light guide did not cause the end product’s bezel to be too large and unsightly.

Thanks to previous collaboration with our team and our proven process, the customer knew they could rely on Global Lighting Technologies to deliver on what was agreed upon.

The Solution: Thin Film Embossing

Light guides for a next-generation watch could take about a year to develop if our customer partnered with an unfamiliar manufacturer. However, our experience with their process and team created efficiencies during this project. Our engineers closely collaborated with this customer’s team to understand their illumination goals. From there, thin film embossing emerged as the optimal manufacturing process for this project. It can produce ultra-thin light guides at high volumes; we crafted this watch backlight to be 0.2mm thick.

To begin the design process, we gathered CAD data from the customer along with brightness and uniformity specifications. Our advanced simulation capabilities allowed our team to meticulously fine-tune LED locations and optical patterns using ray tracing software. In the simulation, individual light rays were cast in the light guide to see where light would go in the real, physical product. This information was crucial for the custom optical pattern development.

From there, we created prototypes which were tested and approved. The smartwatch backlight was crafted at our facility in Zhongli, Taiwan then placed in the final assembly at our facility in Shanghai, China.

The Results

The project, from conception to market launch, spanned just about six months. We supplemented efficiencies gained from past projects with this customer with our agility and commitment to meeting tight deadlines. Their satisfaction was evident as the application successfully hit the market, where it continues to garner praise for its high performance. While specific sales figures were not disclosed, the product’s reputation as a well-respected solution underscored its commercial success.

Custom Backlight Light Guide Design

When production requires a thin light guide produced in hundreds of thousands to millions, consider thin film embossing. Visionary companies turn to Global Lighting Technologies for the latest in LED light guide technology, strategic guidance (like selecting a production process) and high-quality results. Support your ambitious goals with a custom light guide design. Connect with our team to bring your bright idea to life.

Learn about backlights vs. front lights.